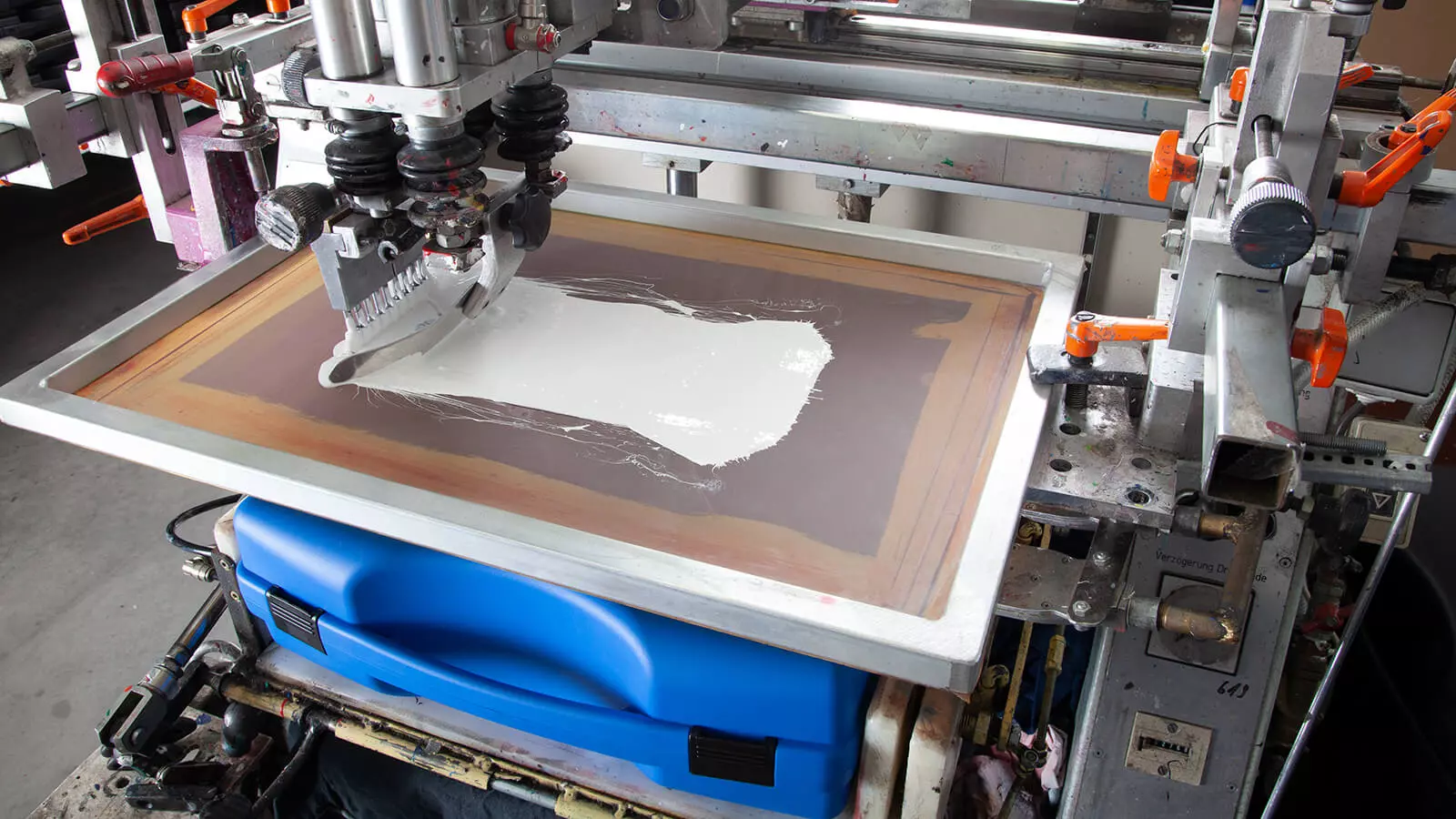

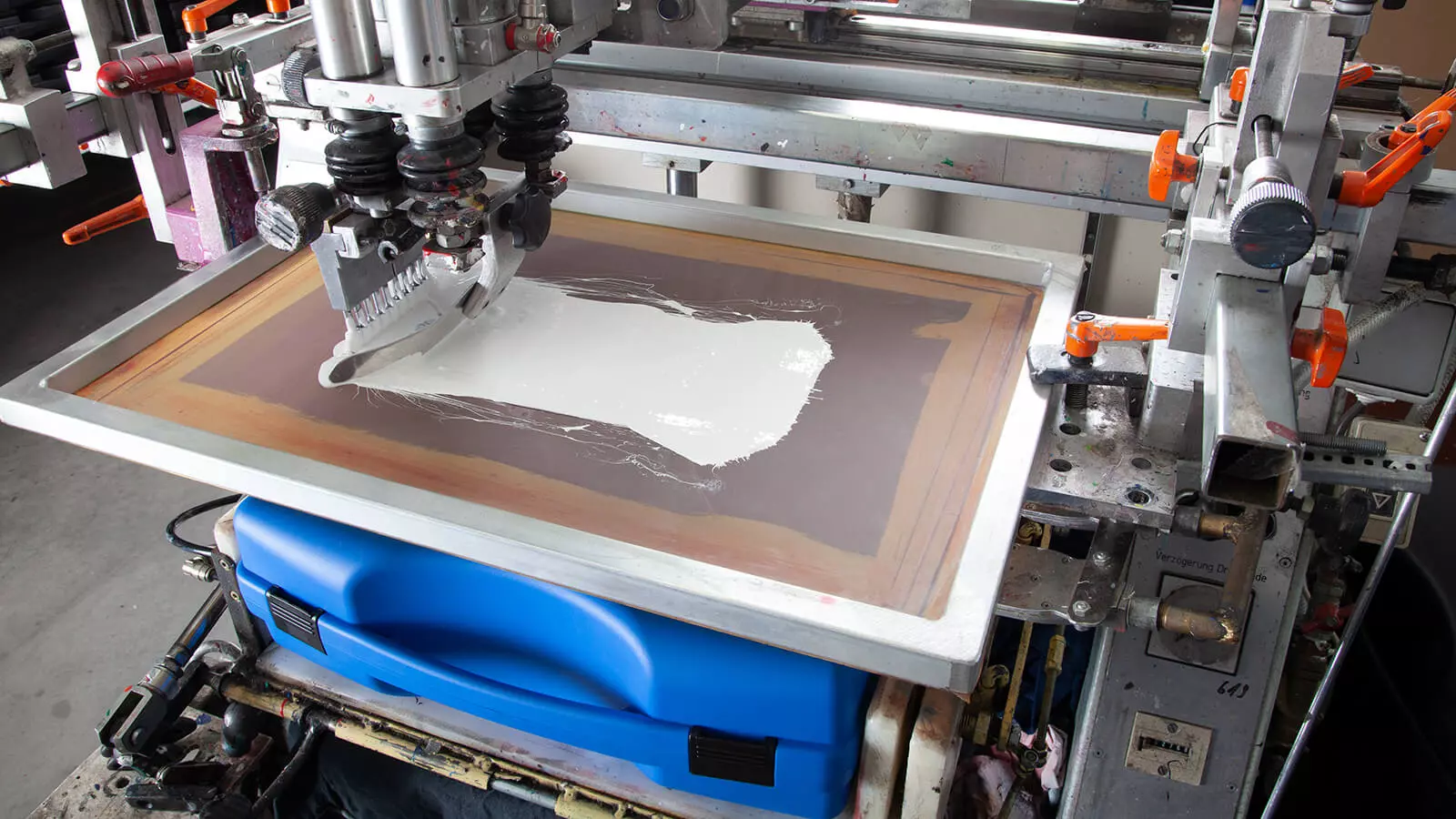

Screen printing

You can print your case shell and case sides with your own logos, word marks or product information using single or multi-colour screen printing. The screen printing process offers you the following advantages:

- Suitable for all W.AG cases

- Can be realised for high-gloss and textured surfaces

- Single-colour and multi-colour prints possible

Pad printing

The pad printing process is generally used for small print areas such as suitcase latches or narrow suitcase sides that cannot be realised with screen printing:

- Customised pad printing possible for all W.AG case series

- Latches and case sides can be customised

- Your logo, slogan or product name can be displayed with high colour intensity

Printing process of

screen and pad printing

Screen and pad printing were the first printing processes that W.AG offered its customers. It is astonishing that these classic printing processes have lost none of their popularity since then.

Experience and personalised advice

Our pre-press department coordinates your screen printing or pad printing motif with you. The experienced staff in the screen printing department expose and stretch the screens in-house at W.AG and match your colour requirements to the RAL colour system.

Our screen printers will then print your case shells, clip fasteners or case sides and turn your case into a durable information carrier.

Do you have any questions?

Get in touch now